From Lab to Clinical Development: CMAC’s Impurity Rejection Workflow

Researchers at Eli Lilly and Company have successfully applied CMAC’s impurity rejection workflow in clinical development, achieving up to 100% rejection of problematic impurities.

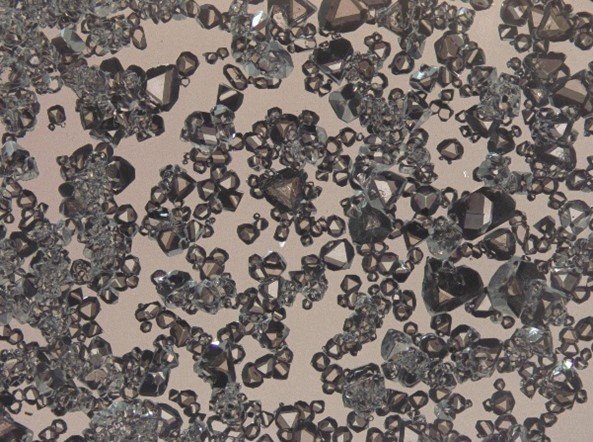

Figure. Impurity Rejection Workflow

The Challenge

The isolation of high purity crystalline compounds is a critical step in the manufacturing of safe medicines. One common purpose of a crystallisation process is to reject (remove) impurity compounds from a mixture. If residual impurity compounds remain in a product, they could have unwanted, or even detrimental, biological effects for the patient. However, removing high concentrations of impurities through crystallisation can be challenging, and impurity rejection is typically tackled on a case-by-case basis.

The Solution

The CMAC Impurity Rejection Workflow (a key output from CMAC’s Impurity Rejection Core Project) was co-created with industry experts from Eli Lilly and Company, Pfizer and Bayer. CMAC researchers formulated a systematic workflow in which the user rapidly generates a targeted problem-solving approach to manage and reduce the levels of impurity in crystallisation products, accelerating the development of medicines.

CMAC’s six-stage impurity rejection workflow involves gathering evidence to sequentially support or disprove the different possible impurity incorporation mechanisms of agglomeration, surface deposition/absorption, inclusion, and solid-solution formation. The experiments are simple, require only standard laboratory equipment, and are resource-efficient, implementing material-saving strategies. Within our labs at the University of Strathclyde, the workflow was applied to seven different example systems, all based on generic APIs, where we demonstrated effective discrimination between the various mechanisms of impurity incorporation. Exemplary translation to industry was then achieved through a series of webinars and training workshops.

Impact

In a recent publication, Eli Lilly and Company researchers successfully implemented the workflow in the crystallisation of a drug candidate in clinical development, reporting three case studies with increasing complexity of impurity incorporation.

These case studies highlight the benefit of the CMAC Impurity Rejection Workflow and how it can be applied to streamline crystallisation process development for controlling impurity related Critical Quality Attributes (CQAs).